A Finish Thompson centrifugal pump has been used to withstand the rigorous conditions found in ultrasonic cleaning machines including the need to transfer volatile, near boiling solventss. The pump was supplied to Guyson International for testing on a demonstration machine by Michael Smith Engineers, the UK distributor for Finish Thompson Pumps.

A Finish Thompson centrifugal pump has been used to withstand the rigorous conditions found in ultrasonic cleaning machines including the need to transfer volatile, near boiling solventss. The pump was supplied to Guyson International for testing on a demonstration machine by Michael Smith Engineers, the UK distributor for Finish Thompson Pumps.

Yorkshire-based Guyson International, is an independent manufacturer of blast finishing, spray wash and ultrasonic cleaning equipment, supplying equipment, spares and consumables. Its ‘Kerry’ ultrasonic cleaning equipment includes aqueous and solvent based systems which have applications in precision engineering, electronics, aerospace, metal finishing and medical manufacturing.

Ultrasonic cleaning works by introducing energy into a tank containing the cleaning solution and this causes minute bubbles to form and collapse within the solution. This action is cavitation and results in a gentle, yet effective scrubbing action on the component surface which loosens the contaminant.

Ultrasonic cleaning is said to be a rapid and highly effective method of precision cleaning of components. Where manual cleaning or spray wash methods are less effective with blind holes, tube internals or difficult to reach crevices, ultrasonic cleaning is an effective alternative.

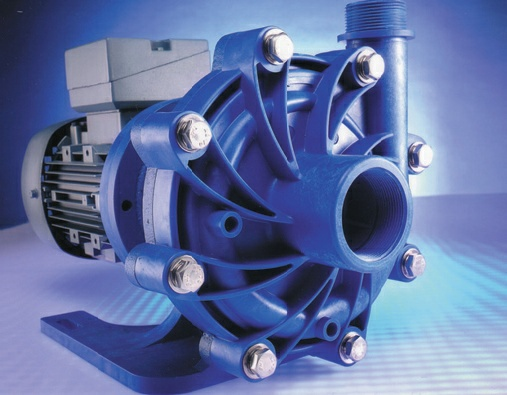

The pump, a magnetically coupled centrifugal model in PVDF construction, was selected following in-service reports which identified the potential for failures of the main circulation pumps on some models of their solvent cleaning machines. Guyson identified that the combination of handling volatile, near boiling point solvents with a very low suction head had resulted in very low pressures at the pump inlet. On many other types of pump this would cause severe cavitation and lead to failure.

The DB pump was tested on a demonstration ultrasonic cleaning machine and found to perform very well without any failure, under all test conditions. After extensive running the pump was stripped down and inspected for wear. All were found to be in perfect condition.

Michael Smith Engineers

T: 0800 316 7891