J D Neuhaus, one of the leader in air hoists, cranes, trolleys and monorail hoists, is now introducing a range of C rail and light crane systems for operation with the company’s established mini air hoist range. Both the C rail/suspension tracks and the light crane systems are rated for use in explosion and hazardous dust-laden areas up to ATEX Zone 2, 22.

J D Neuhaus, one of the leader in air hoists, cranes, trolleys and monorail hoists, is now introducing a range of C rail and light crane systems for operation with the company’s established mini air hoist range. Both the C rail/suspension tracks and the light crane systems are rated for use in explosion and hazardous dust-laden areas up to ATEX Zone 2, 22.

Featuring high quality standard elements, the modular C rail systems/suspension tracks make for simple assembly and smooth movement of loads in accordance with individual customer requirements. The units, which are suitable for flexible material transport applications, are purpose-engineered to offer high durability when deployed in challenging environmental conditions.

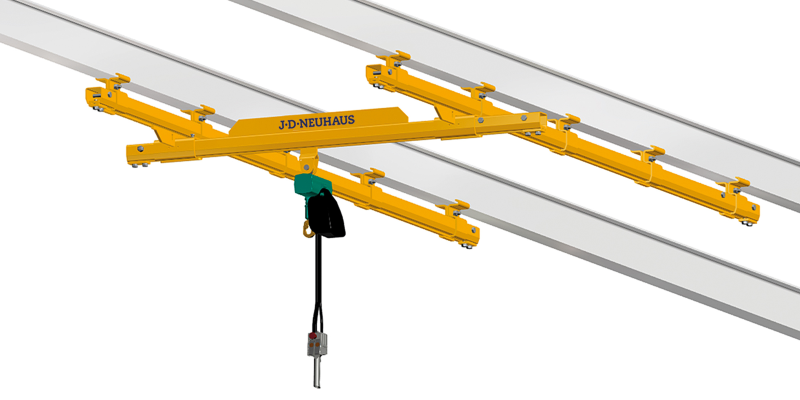

Similarly, the light crane systems offer easy adaptation to load and operating conditions. Available in four standard profile sizes, design modularity again provides users with the opportunity for light and easy assembly, the result of which is smooth movement of the reinforced crane bridge and optimal space utilisation at low headroom conditions. Air delivery is facilitated via hose trolleys in the crane rail.

To help maximise system life, users can pick from a range of surface protections for the crane rail and trolleys, including coated, zinc-plated or chromated, while stainless steel is available as an option for lighter capacities of 100 and 200kg.

Both the light cranes and C rail/suspension tracks give provision for straightforward system extension to accommodate changing requirements over a working life.

The crane track length is fully selectable in accordance with customer requirements, while the bridge length can be specified up to a maximum of 6000mm as standard, with larger sizes available upon request. Track width is dependent upon the bridge length, but typically, a system with a carrying capacity of 125kg would dictate a maximum track width of 4,500mm. This rises to 5,000mm for carrying capacities of 250, 500 and 980kg.

The crane track length is fully selectable in accordance with customer requirements, while the bridge length can be specified up to a maximum of 6000mm as standard, with larger sizes available upon request. Track width is dependent upon the bridge length, but typically, a system with a carrying capacity of 125kg would dictate a maximum track width of 4,500mm. This rises to 5,000mm for carrying capacities of 250, 500 and 980kg.

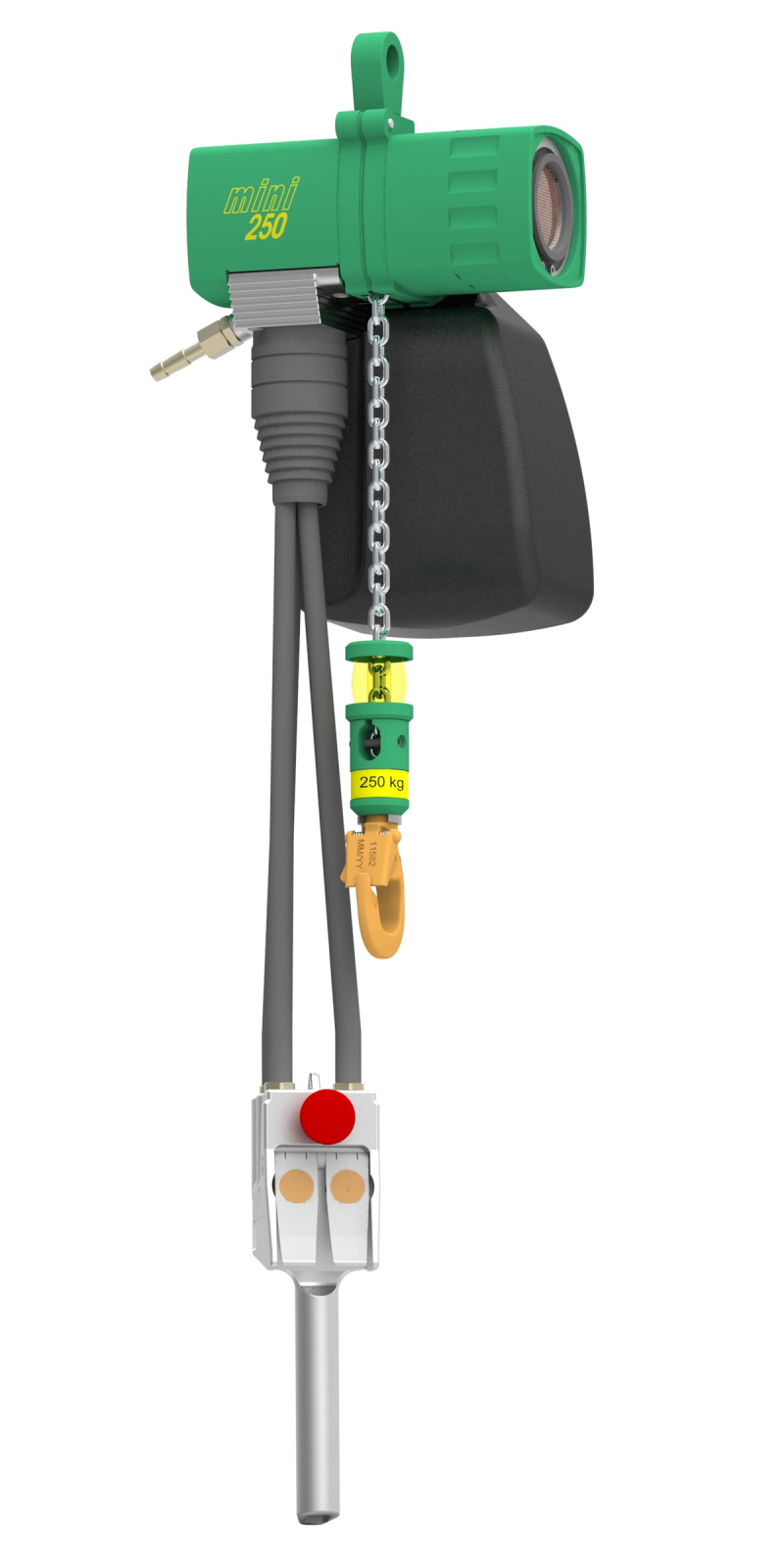

The carrying capacities are of course determined by the choice of pneumatic hoist utilised. Here, JDN offers its mini 125, mini 250, mini 500 and mini 1000 models, which are not only offer lube-free operation for use in hazardous areas, but a price-competitive alternative in comparison with other types of powered hoist.

Principal advantages of JDN mini air hoists include minimal components for ease of maintenance, a wear-resistant motor braking system and suitability for horizontal pulling (in addition to conventional lifting and lowering). Where fitted with an extremely sensitive lever control featuring an emergency shut-off valve, lifting heights of up to 8m can be specified.

With over 200 employees across the group, J D Neuhaus manufactures pneumatically and hydraulically-operated hoists and crane systems up to 115 tonne capacity from its state-of-the-art facility in Witten, Germany.

Resilience and reliability are the key product differentiators, thanks largely to the company’s explosive protection rating which makes them ideal for use even in the most challenging of operating environments. Extreme applications include oil and gas exploration in arctic temperatures as low as 45°C, along with underwater tasks such as ship hull repairs, and plenty of others in demanding sectors like mining, the chemical industry, heavy plant construction and many areas of logistics.

The wide portfolio of services provided by J D Neuhaus includes equipment assembly, inspection, maintenance and general overhaul, along with the supply of customer training courses.

Over 80 per cent of production from the Witten, Germany plant is exported, which is why the company has long-established subsidiary companies in France, UK, Singapore and the USA, all of which have helped create a tight-knit global network in collaboration with international partners.