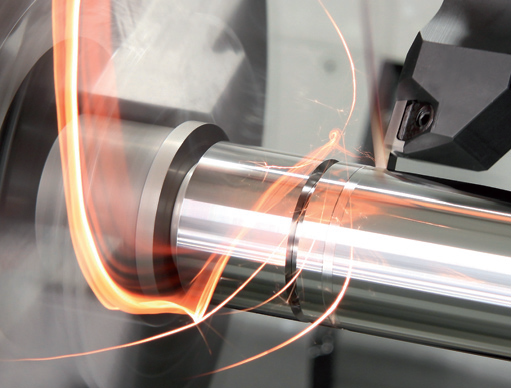

Addressing the challenges of machining hard materials, grooving tools in the new VersaCut range from Mapal combine stability, thanks to their insert clamping system, with versatility – just one type of tool holder is all that’s needed to accommodate inserts for all standard grooving and turning applications.

Addressing the challenges of machining hard materials, grooving tools in the new VersaCut range from Mapal combine stability, thanks to their insert clamping system, with versatility – just one type of tool holder is all that’s needed to accommodate inserts for all standard grooving and turning applications.

VersaCut tools use long-life inserts that are retained in the tool holder by a clamping jaw that presses them securely into a prismatic connection. Because of the large clamping force used, this arrangement provides the stability needed for precision machining, but the design of the clamp also allows the inserts to be changed easily and quickly.

The clamping jaw is recessed into the tool holder to ensure unimpeded chip flow and to protect the jaw against wear. Because of the special geometry of the inserts, the risk of damage to the tool holder should the insert fracture is virtually eliminated.

PcBN inserts for the VersaCut range are available in four standard types to suit all common machining applications. Mapal can also supply PCD-tipped inserts and custom-designed inserts for special requirements.

All inserts have the same connection shape and size, which means that only one type of tool holder is needed for grooving depths up to 5mm and grooving widths from 1.2mm to6 mm.

Mapal T: 01788 574700