An analysis of the operation of a machine will identify movements which constitute elements of a hazard. These are the elements which could simply be expressed as constituting ‘clear and present danger’ to the operator. In the face of this danger to personnel there is no room for complacency says Sick safety specialist, Seb Strutt

An analysis of the operation of a machine will identify movements which constitute elements of a hazard. These are the elements which could simply be expressed as constituting ‘clear and present danger’ to the operator. In the face of this danger to personnel there is no room for complacency says Sick safety specialist, Seb Strutt

Despite having one of the most comprehensive safety regimes in the world due to successive machinery safety legislation and associated technical standards in the EU, Strutt believes we can’t sit back and assume all is right.

Safeguard positioning

The introduction of BS EN ISO 13855:2010 ‘Safety of machinery – positioning of safeguards with respect to the approach speeds of parts of the human body’, highlighted how machinery operators might put their safety at risk, without knowing it. Thus, it is vital a protective measure can react in time. Incorrect positioning of the safety device is one of the most common reasons for compliance failure. Sick has observed this on countless occasions during initial safety inspections, yet the provisions and implementation are simple and compliance can easily be achieved. The standard BS EN ISO 13855:2010 is an excellent step forward, and fills an important gap in the previous standard. What must be accurately measured, by a competent person, is the distance from the hazard point to the safety device and its orientation relative to the hazard. However, the precision required for complex safe distance calculations and the need for accuracy in estimating the safe stop time of the hazardous movement, is vital to achieving compliance.

Compliance with confidence

Compliance with confidence

Manufacturer derived safety distance calculation tools and stop time measurement services can remove the uncertainty from the required measurements, and establish the exact distances needed for compliance. By taking advantage of these, or using measurement services, the engineer gains peace of mind and reduces the risk of accident. Identifying the minimum safe distance measurement is critical. This is why Sick offers a stop time calculation service prior to and following installation of new safety measures.

Positioning preventive devices

BS EN ISO 13855 applies to safety light curtains as well as other preventative measures such as pressure sensitive mats and two hand control systems. The standard is intended to ensure accessible hazards with mechanical movement are protected by an electro-sensitive protective device (ESPE). This device can detect an approach to the hazard and initiate a stop command which brings the mechanical motion to a safe condition.

Distance calculations

A good example is a typical hand-fed machine press. In the event that work is misplaced, a common operator response is to try and grab the item during the down stroke of the press. The operator’s hand speed could easily reach two metres a second. If the protective light curtain is positioned too close to the press a hand could reach the hazardous zone before the press can react to the curtain’s stop command – the consequences could be devastating.

For a vertical light curtain, the safety distance (safety reach through or Srt) is calculated from the speed of approach (K) multiplied by total response time of the machine (T) plus a constant (C) dependent on the specification of the light curtain, Srt = (K*T) + C. With a full body access detection multiple beam light guard (typically three or four beams), the equation becomes, Srt = (K * T) + 850mm. When using multiple beams, the minimum safety distance should be greater than 850mm to accommodate the arm length when reaching through the light beam grid.

Hazardous reaching over

Hazardous reaching over

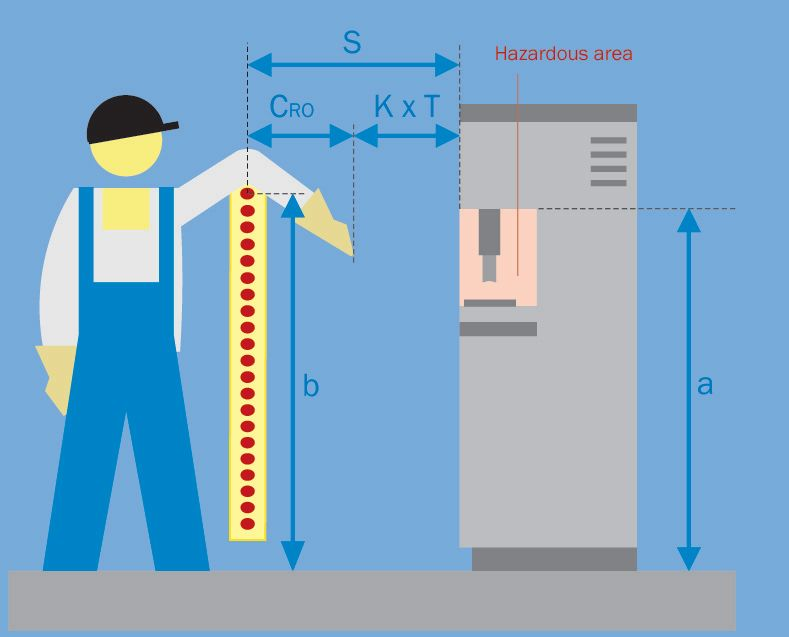

The completely new element of the 2010 standards tackled the problem of operatives reaching over light curtains. The height of the hazard from ground level, when reaching from a standing position, is a major deciding factor in the height of the top beam of the light curtain.

The reach over safety distance (Sro) is calculated by adding a specially measured constant (Cro) into the equation, Sro = (K*T) + Cro – (see diagram top).

Cro is derived from the table above. Areas of the table marked ‘0’ show where the hazard cannot be accessed by overreaching. This means a hazard height of 800mm, with the upper edge of the light curtain detection zone at 1,600mm, cannot be accessed by overreaching. If the standard Srt safety distance is also calculated for the set-up, the resultant safety distance adopted should be whichever is greater – Srt or Sro. The results can be attached to the machine under scrutiny, as an immediate guide to its safe operation and safety status.