Fruit specialist, Fruit Gourmet, has selected an Ishida X-ray inspection system from Ishida Europe for enhanced quality control. The decision to install this machine follows the success of Ishida multihead weighers at the site.

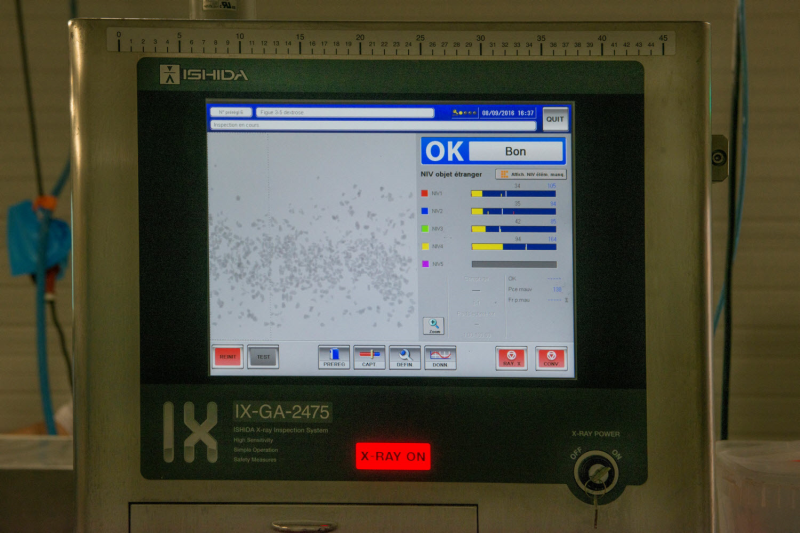

Fruit Gourmet supplies a variety of fruits, including prunes, apricots, figs, grapes, mangoes, strawberries, raspberries, apples, blueberries, bananas and cranberries, sold to the consumer as cooking ingredients and as healthy snacks, packed in bags as well in bulk. The Ishida IX-GA-2475 X-ray model is being used for the inspection of bulk streams of the fruit pieces.

Careful supplier selection and long processing experience means that products such as Fruit Gourmet’s shredded apricot rarely contain contaminants. However, the Ishida X-ray inspection system, already highly sensitive, can be set to even higher levels of sensitivity for the contaminants that have historically been known to occur in such agricultural products, such as minute particles of glass, stone or buckshot.

Careful supplier selection and long processing experience means that products such as Fruit Gourmet’s shredded apricot rarely contain contaminants. However, the Ishida X-ray inspection system, already highly sensitive, can be set to even higher levels of sensitivity for the contaminants that have historically been known to occur in such agricultural products, such as minute particles of glass, stone or buckshot.

One aspect that particularly appealed to Fruit Gourmet was the Ishida’s evolutionary image processing software, which enables the operator, without any special training, to automatically generate the optimal sensitivity setting for each inspected product.

Hygiene was another factor, with the IX-GA’s design practically eliminating areas in which product can build up.

A well-known slogan of Fruit Gourmet has the product itself saying “I am not the fruit of hazard”, meaning that its level of quality did not just happen by chance but is the result of many years of experience combined with excellent raw materials, expertly selected.

CEO, Emeric Cadalen, sees the security offered by the new Ishida X-ray inspection system as just one more extension of this approach, in which nothing is left to chance.

The adoption of X-ray technology continues Fruit Gourmet’s relationship with Ishida, which began in 2014 when it was decided to create a new packing line for bagged products with target weights of 50 to 500g.

The adoption of X-ray technology continues Fruit Gourmet’s relationship with Ishida, which began in 2014 when it was decided to create a new packing line for bagged products with target weights of 50 to 500g.

The company put this project out to tender, resulting in the acquisition of a 14-head multihead weigher from Ishida. The company won the tender because its proposed model was closely matched to the needs of rehydrated fruit packing. Measures to keep the sticky products moving smoothly through the weighing process included steeply sloping surfaces, with dispersion cone, dispersion table and all hoppers specified in embossed stainless steel and with the timing hopper beneath the weigher equipped with scraper gates.

Speed of cleaning was another success factor. Key points here were the open, accessible structure of the weigher and the fact that contact parts can be lifted off and replaced by hand without tools.

The proximity of Ishida technical help was a third decisive factor for Fruit Gourmet.