In an increasingly globalised world, the need for greater supply chain transparency has become a crucial issue for manufacturers and retailers, with sustainability continuing to be a hot topic. Ethical practices in the supply chain are set to continue, with organisations needing to focus on how they can reduce their environmental impact.

In an increasingly globalised world, the need for greater supply chain transparency has become a crucial issue for manufacturers and retailers, with sustainability continuing to be a hot topic. Ethical practices in the supply chain are set to continue, with organisations needing to focus on how they can reduce their environmental impact.

Warehousing and logistic facilities play a vital role in the overall supply chain process, with storage and space being a fundamental factor for warehouses to achieve both efficiency and effectiveness for their overall business functions.

In such a rapidly changing world many companies put innovation at the forefront, in the constant strive to meet the demand for more effective, efficient and sustainable product designs. Quality has become imperative in protecting goods during transit and storage along with an increase in needing to be mindful of the environmental considerations that are intrinsic to the world of packaging.

Kite Packaging, one of the UK’s leading packaging distributors, supply a range of unique reusable plastic containers, designed to help solve handling and logistic problems for a wide range of industries, along with the widest range of quality stretch films in the UK to support against waste and protection during transit.

The container range sold by Kite focuses on increasing load stability, reducing packaging waste, increasing vehicle fill, reducing labour, transport and consumable costs and increasing efficiency throughout industry supply chains.

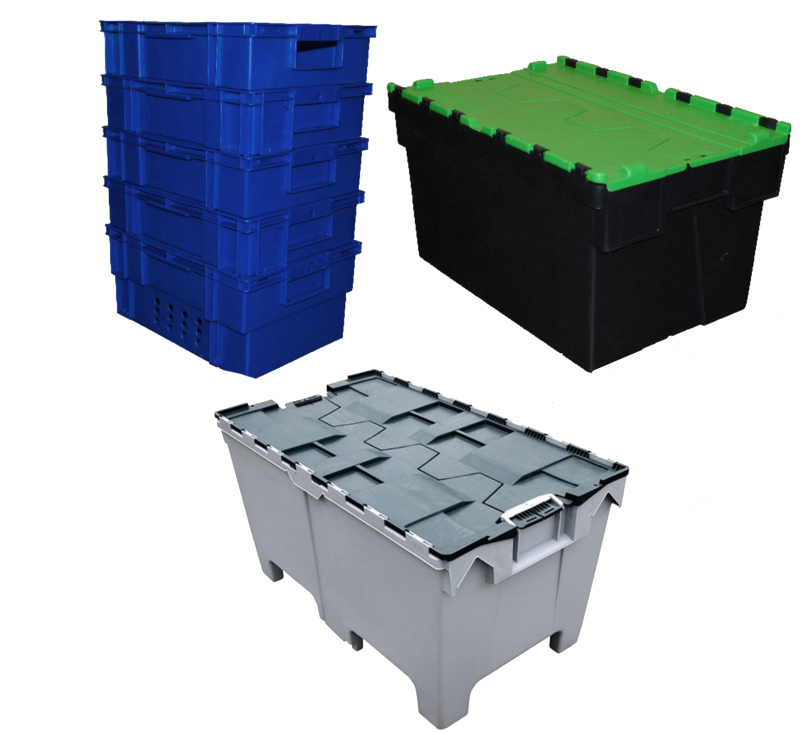

Consisting of a range of attached lid containers, stackable / nestable containers and plastic pallet boxes, these versatile, robust and reusable products are widely used by companies looking for a multi-trip, reusable solution where efficient handling and storage are key. The innovative lid design allows the lids to secure in a vertical line, meaning no lid overhang.

Available in a range of sizes, the attached lid containers work well as a standalone product, however, are also impressive as part of a modular system. They come in a range of different strengths, virgin material – produced from high impact polypropylene. Repro/virgin – consisting of a recycled polypropylene base and virgin polypropylene lid and repro – consisting of recycled polypropylene. Stacking safely when full and nesting when empty, they save up to 65% space in storage.

Stack and nest containers are a full virgin material container produced from polypropylene that stack safely when full and nest when empty. The easy to use container protects products during picking assembly, processing, and storage and distribution applications. Available with or without a lid, all containers come with handgrips to ensure efficient manual handling.

The plastic pallet box has been designed as an end-to-end transit system, produced from a tough polyester powder coating; the unique half UK pallet size box is the only stackable and nestable product of its size and incorporates the clever lid design that means the lids sit flat against the box when nested. Designed to be lifted with appropriate machinery, such as forklifts and pump trucks, the patented design provides the perfect balance of carrying capacity and easy handling.

A range of specialised accessories are also available, please contact Kite for more information

Kite supplies the widest range of quality stretch wrap films in the UK market with specifications to suit all applications consisting of, hand films, machine films, mini wrap / spiral wrap, ventilated stretch film and printed stretch film. Kite regulates all production tolerances to guarantee roll length, thickness and weight.

Hand wrapping pallets is a very common warehouse operation and unfortunately, so are the health and safety issues and costs that come with it. Kites 5×5 hand dispenser, can help solve these problems. Designed to improve efficiency and comfort of wrapping, the 5×5 requires no bending or stretching and requires the operator to walk forward, improving wrapping speed and reducing fatigue. Ensuring pallets are uniformly wrapped and less film is wasted, the 5×5 hand dispenser applies hand stretch film around pallets just like a machine.

The 5×5 consistently wraps pallets and reaches optimum level when the film is stretched – improving puncture resistance. The pre-stretch rollers provide efficiency with an average time of 1 minute to wrap a pallet. The system requires less stock and reduces storage by 60% and decreases packaging waste by up to 70%.

Stretch wrap is a significant expense. Businesses often do not look at the stretch wrap being used and the process of wrapping when operational issues occur. Kites specialist team of highly experienced stretch film engineers carry out scientific stretch wrap audits. It is important new and existing customers carry out an audit, focusing on the stretch wrap technique, the wrap being used and the holding forces involved.

Stretch wrap is a significant expense. Businesses often do not look at the stretch wrap being used and the process of wrapping when operational issues occur. Kites specialist team of highly experienced stretch film engineers carry out scientific stretch wrap audits. It is important new and existing customers carry out an audit, focusing on the stretch wrap technique, the wrap being used and the holding forces involved.

For more information on Kites products and services, please visit www.kitepackaging.co.uk or call 02476 420065.