A number of key objections can be put forward against the automating of a manufacturing process. Some of the most common of these are cost; available space, and the lack of flexibility of the automation system. However, as REM Systems explains, when applied correctly automation can deliver considerable cost savings and increased manufacturing capacity.

For many, machine tool automation starts and ends with standalone, multi-axis robots, that have been made familiar by scenes of high volume manufacturing plants with sparks flying from spot welders, or robot arms spray painting cars. “Now is the time for smaller businesses to start to think outside the box when it comes to maximising productivity and adopting lean manufacturing practises,” states Ian Holbeche, Managing Director of Automation specialist REM Systems. “Our typical automation customer manufactures high value components on 5-axis machines. Their production is predominantly complex components in high variety, low volume with 50-off being considered a large batch. This is so far away from what is perceived as typical automation territory, without a ‘typical’ robot in sight.”

With a standalone industrial robot space is a major issue as the arc of movement of the robot arm has to be accommodated and, if multiple machines are to be supported by a single robot they have to be positioned radially around the robot potentially wasting valuable floorspace. A linear system, with the robot moving along a line of machine tools is much more space efficient. So, once the myth that robots only come in one shape is dispelled the next obstacle to overcome is the fear of many small- to medium-sized manufacturing companies that automation is expensive and cumbersome.

“Some machine suppliers do offer automation solutions, but they are often restricted to a limited range of automation that can be both expensive and inflexible, and are not tailored to the customers’ specific needs,” Ian Holbeche points out.

For example, many OEM supplied automation systems will feature fixed sized pallets that match the size of the machine table. Having pallets that match the size of the workpiece has several advantages, including better access for cutting tools, and a lower investment cost. Of course, REM Systems customers have a high mix of components that means small pallets are not always the answer. This is why the ability to mix and match pallet sizes within an automation system is essential for efficient operation.

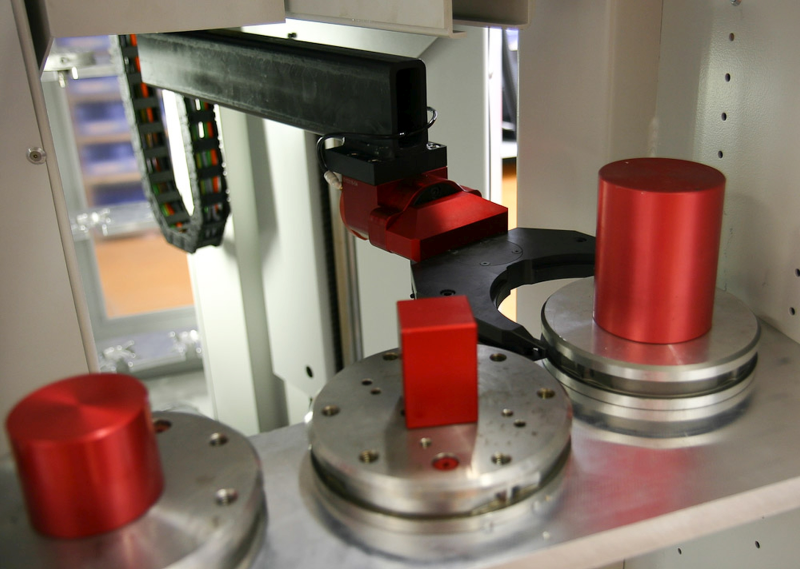

The Robot Easy is part of the overall range of automation systems available through REM Systems. These systems can be as simple, or as complex, as the application demands. For example, the popular Erowa Robot Compact system takes up just 2 m2 of floorspace with as many as 200 different positions in the storage magazine. For even greater capacity and flexibility the Erowa Robot Dynamic system can store a mixture of up to 1,200 pallets. It can automatically change its gripper to suit different sizes of pallet/component and the robot itself travels along a rail to support up to eight independent machine tools.

“Being independent of any one machine tool company we feel that we can discuss automation in an open and objective way with our customers and in doing so achieve the optimum solution in terms of productivity, flexibility, and cost. Automation is an investment that offers many positive benefits to machine tool users, it certainly shouldn’t be something that gives you sleepless nights,” says Ian Holbeche.

He concludes: “If you are still unsure if automation is for you, REM Systems is happy to provide a free of charge consultation to look at specific requirements and provide an honest assessment of whether automation can bene?t your production needs.”