Montech AG is launching the new RB4020 and RB5025 gravity roller conveyors, which can be precisely adapted to products, processes, and layouts

The modular system, available in various designs, fulfills all the requirements of modern conveyor technology and is fully compatible with existing Montech conveyor systems.

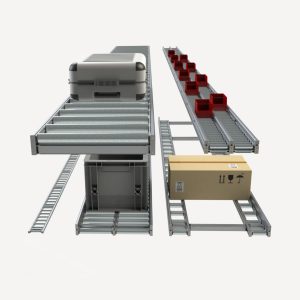

Our new roller conveyors come in two sizes: the RB4020, with a 20-millimeter support roller, is ideal for smaller, lighter goods. In contrast, the RB5025 roller conveyor with a 50-mm support roller is suitable for larger, heavier products. Both variants are available in single-, double-, multi-, and tandem configurations.

Unique advantage: Fully configurable system solution

“In contrast to many competing products, Montech not only provides custom roller conveyors, but also a continuous, freely configurable system for maximum flexibility,” says Murat Simsir, CSO at Montech. “Our customers choose the conveyor width, roller spacing, and track length to the millimeter, without specifications, and precisely matched to the goods they are conveying. This means that several roller conveyors of different designs, sizes, and lengths can be combined to form a complete custom solution. Supplemented by side guides in various designs and a substructure built with the precise MPS aluminum framing system, the result is a fully configurable, integrated roller conveyor system. “This modular approach reduces planning effort, avoids interface problems, and ensures process reliability during operation,” says Murat Simsir.

A wide range of applications, from logistics to the airport

The new RB4020 and RB5025 roller conveyors are designed for a wide range of industries and applications. Typical applications include logistics, packaging, plastics processing, automotive, and order picking and shipping. The new gravity roller conveyors are also suitable for use at airports – for example, for security checks and luggage transport – as well as in e-commerce providers’ large distribution centers. “Thanks to their modular design, the systems can be integrated seamlessly into existing systems and extended at any time if required,” explains Murat Simsir.

Short delivery time despite custom production

Whether it is a compact single-track solution, a double-track roller conveyor for maximum load capacity, or a tandem version with a wide conveyor, each roller conveyor is manufactured individually. “Nevertheless, Montech guarantees a delivery time of just seven working days,” says Murat Simsir. This is possible thanks to the components’ high degree of standardization and the conveyor system’s modular design. Users receive custom-tailored conveyor technology delivered quickly and ready to use.

For more information, visit Montech: conveying and profile technology