IMI Precision Engineering has launched new ranges of safety valves through product brands IMI Norgren and IMI Herion, providing protection for operators and their machines from the possible hazards of compressed air in industrial automation applications

New to the electrically-operated safety valve market are the SCVA and SCSQ cross monitored safety valves – with the latter also offering integrated soft start. Designed to render complex machine systems safe in the event of an emergency, the SCVA cross monitored safety valve is a pneumatically-monitored dump valve which meets the DIN EN ISO 13849 standard and is DGUV certified for category 4 performance level e. The SCVA valve’s very high reverse flow of up to 30,000l/min allows downstream air to be exhausted in the shortest possible time, and requires no additional electronic monitoring. Easy to retrofit onto existing machines, the valve requires only 40µ filtration making it a highly cost-effective option which also offers a long service life even in high-frequency switching applications thanks to its excellent B10 values.

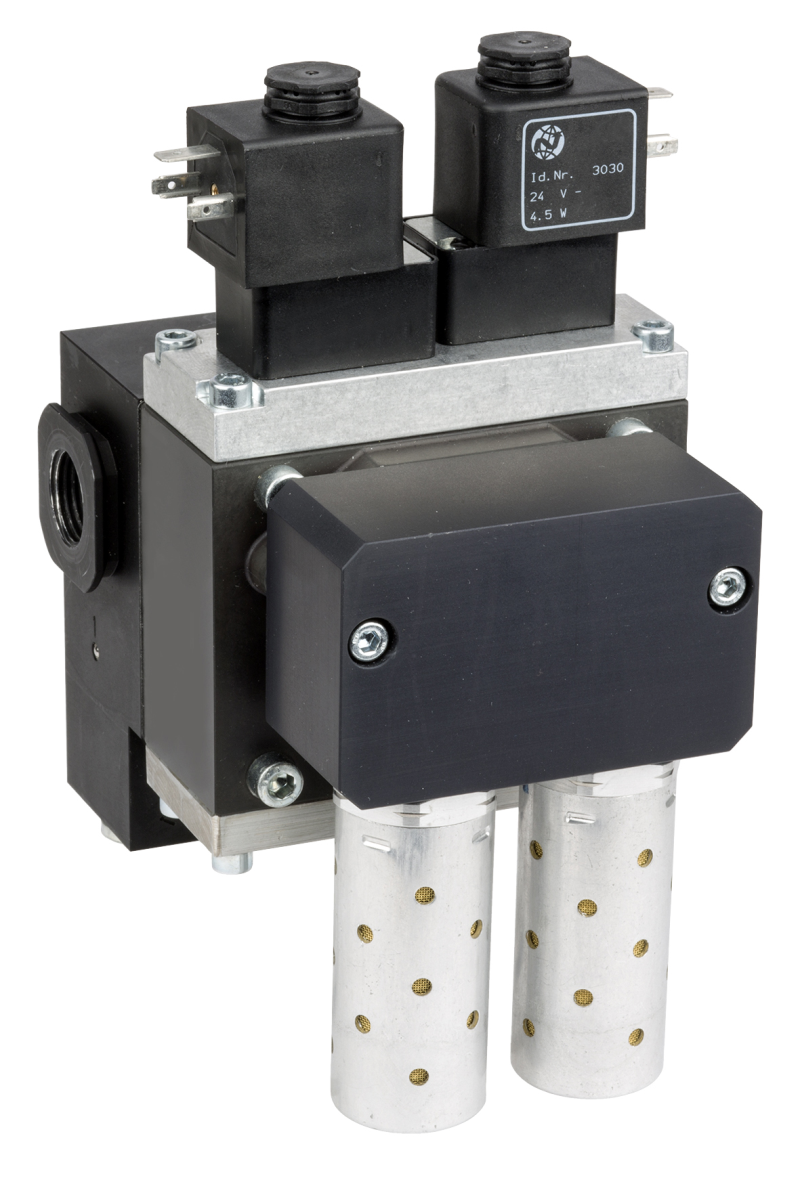

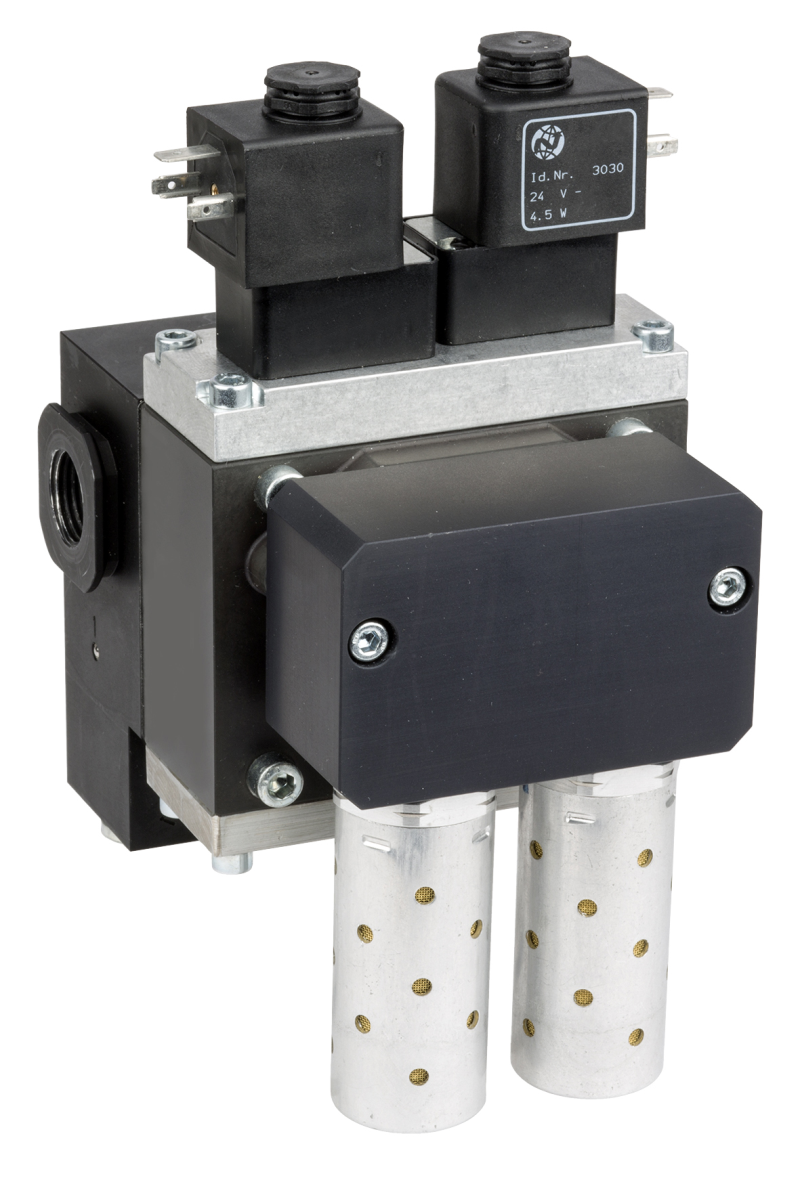

Joining the SCVA is the SCSQ cross monitored safety valve, engineered to provide a controlled restart of air supply which can be adjusted to suit the downstream volume and required fill rate. Similar to the SCVA, the SCSQ comes complete with an exhaust silencer. The new valve also meets DIN EN ISO13849 standard, is DGUV certified for category 4 performance level e and meets outstanding B10 values. The SCSQ valve also provide flexible installation options, as it can be mounted as part of a control system or alternatively connected via integral adaptors to air preparation units.

The XSZ range of fail-safe safety valves incorporates both 3/2 and 5/2-way pneumatic actuated or solenoid actuated valves. Both models offer inherent fail-safety with no residual pressure as well as dynamic self-monitoring and a fast exhaust capability. The pneumatic actuated models seamlessly integrate into two-hand control systems meaning they conform with DIN EN 574 as well as the DIN EN ISO 13849 standard. The solenoid actuated range also meet the latter standard, with the 3/2-way option being ideal for use with pneumatic clutch and brake systems as well as other 3-way safety functions.

In addition, the VSP valve range provides reliable service in challenging applications, available as a 5/2 functional type and equipped with optional electrical position monitoring. With the appropriate pneumatic application, a redundant system with high category and performance levels according to DIN ISO 13849 is achieved. As a result of the valves’ unique design, they also provide high B10 figures. For applications in which safety valves with a minimum operating pressure of 2-3 bar cannot be used, VSP valves with external air supply are ideal as they can be used from 0 bar.

For further information please visit www.imi-precision.com