Manufacturing automation systems are delicate and very expensive pieces of kit, which perform vital functions for the businesses they serve.

Manufacturing automation systems are delicate and very expensive pieces of kit, which perform vital functions for the businesses they serve.

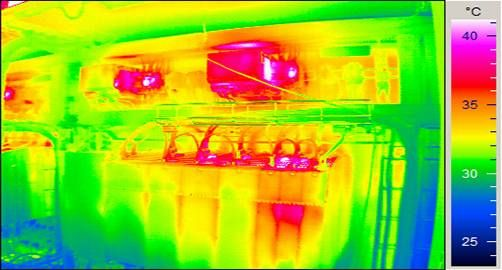

The enclosures that protect them must have strictly controlled internal environments with interior temperatures that are carefully maintained within a few degrees. If not, the impact can be harmful to the inverter drives, power supplies, contactors, PLCs and other electrical and electronic components operating within them. This requires careful control of the climate within the enclosure.

Here, Jason Swann, Rittal Product Manager for Climate offers some practical tips on how to evaluate an existing enclosure climate control through a series of simple checks.

Like all electrical equipment, drives create heat and they therefore have a major influence on the temperatures inside enclosures. Drives are often quoted as having efficiency of 97 per cent, so one with a rated output of 150kW can produce as much as 4.5kW of heat.

Like all electrical equipment, drives create heat and they therefore have a major influence on the temperatures inside enclosures. Drives are often quoted as having efficiency of 97 per cent, so one with a rated output of 150kW can produce as much as 4.5kW of heat.

As well as the heat loss inside the enclosure, ambient temperatures within a production facility will also have an impact on the temperatures that a drive is operating within. A typical enclosure climate control system is designed for an internal enclosure temperature of 35°C. This means that the performance of a cooling unit should be specified so that the average internal enclosure temperature of 35°C can be guaranteed under all load conditions and under all the ambient conditions that could be met at the machine’s location.