At the Fiat factory in Melfi, Italy, where several different Fiat models are being produced, inspections with Flir Systems thermal imaging cameras play an important part in the predictive maintenance program. Information obtained during thermal imaging surveys are used to predict electrical and mechanical faults so they can be fixed before they become production halting breakdowns

At the Fiat factory in Melfi, Italy, where several different Fiat models are being produced, inspections with Flir Systems thermal imaging cameras play an important part in the predictive maintenance program. Information obtained during thermal imaging surveys are used to predict electrical and mechanical faults so they can be fixed before they become production halting breakdowns

Fiat cars are among the most popular in the world. The Fiat 124 was elected best car of the year in 1967 and since then eight other models followed suit in the following years, including Fiat’s current favourite, the Fiat 500 which won the best car of the year award in 2008.

The Italian car manufacturer was founded in 1899 by the Italian entrepreneur Giovanni Agnelli. Since then, Fiat has not only produced consumer cars, but also manufactured railroad vehicles, tanks and aircrafts.

Today it is the largest car manufacturer of Italy and one of the largest in the world. Given that the Fiat factory in Melfi produces cars at a rate of 250,000 per year, it is crucial that the system keeps running all the time. To achieve that goal Fiat needs to ensure every electrical or mechanical fault is spotted and repaired before it becomes a production disrupting failure.

Detecting those faults in time is the task of Raitech Industrial Technologies, a company specialising in technical assistance for industrial machinery.

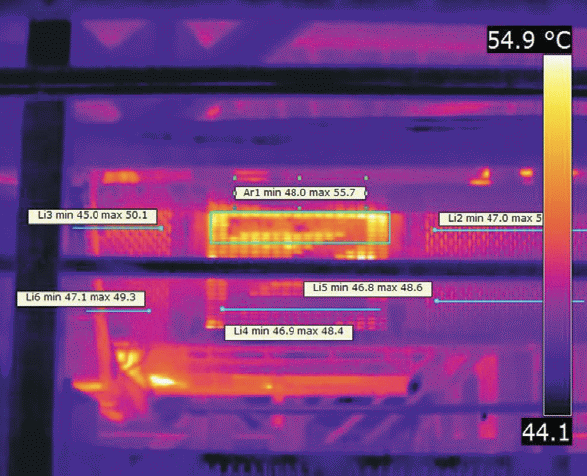

Raitech was founded in 2010 as a division of Raichim Srl that is dedicated exclusively to the industrial sector. Since 2004 Raichim also works for the Fiat Group. Currently Raitech takes care of the technological systems and industrial maintenance at Fiat Melfi. Thermography specialist for Raitech Aldo Alliata says the thermography inspections using thermal imaging cameras from Flir Systems are becoming more important within the array of Raitech maintenance tools. “Thermal imaging technology is the only tool that really allows you to see the problem.”

Flir MeterLink adds value

Recently Alliata has been able to add even greater value to his thermographic inspections at Fiat Melfi with Flir’s Meterlink connectivity solution. It consists of a Bluetooth connection between the Flir thermal imaging camera and an Extech EX845 clamp meter. The measurement data is automatically embedded in the corresponding radiometric thermal image. This functionality improves the accuracy and speed of the thermal imaging inspections, according to Alliata.

The correlation between temperature and electrical load is well established and for years thermographers have included load ratings where relevant. Alliata explains: “The most common way of doing this is to take readings using a clamp meter, write the measurements down on paper and add them to the report later on.” Alliata is a certified Level 3 thermographer and, just like most other consultants, performs more than 100 inspections per year. During these he processes a lot of data and it would be easy for readings from different instruments to get lost or be mixed up.

The correlation between temperature and electrical load is well established and for years thermographers have included load ratings where relevant. Alliata explains: “The most common way of doing this is to take readings using a clamp meter, write the measurements down on paper and add them to the report later on.” Alliata is a certified Level 3 thermographer and, just like most other consultants, performs more than 100 inspections per year. During these he processes a lot of data and it would be easy for readings from different instruments to get lost or be mixed up.

The Flir Meterlink connectivity feature is available on a variety of Flir cameras including the Flir T335 thermal imaging camera used at the Melfi factory. It is suitable for a range of electro-mechanical inspection tasks common at larger industrial plants.

Easy to use

For Alliata, the Flir T335 with Meterlink connectivity is a great asset. “The menu system is intuitive and easy to use and it has many analysis tools that can be set up according to the job’s needs. The Meterlink feature allows the camera to receive data automatically from an Extech EX845 clamp meter. Its effectiveness is obvious, in the field inspection and at the post report processing stage.”

Alliata confesses that due to the Meterlink he is much more likely to take the time to use the clamp meter because it is easier and faster than using paper notes. “I simply apply the clamp meter and the Meterlink system will automatically embed that reading in the appropriate radiometric thermal image,” explains Alliata.

No mix-up

The saved measurements are fully accessible in the Flir analysis and reporting software Flir Reporter and easily added in the results tables. This eliminates all possibility of any mix-up. “This combination of a Flir thermal imaging camera and an Extech clamp meter rules out the possibility of confusing the location, the equipment or load data from individual faults,” Alliata concludes. “In the field I can work more quickly, reducing the amount of time I have to spend in the office, which in turn allows me to spend more time with customers.”