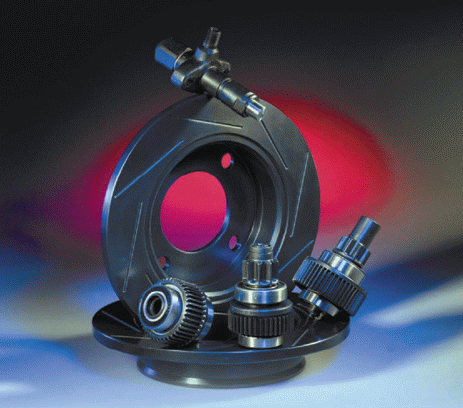

Blackfast Chemicals, manufactures and supplies the Room Temperature Blacking Process for iron and steel. The process is said to be an inexpensive and convenient process developed for in-house use eliminating the need for metal parts to leave the production facility for finishing by an outside contractor. The process requires no expensive capital investment, short dwell time and replenishment is accomplished by ‘topping up’ when the solutions become weak so dumping of chemicals is not necessary. The uniform matt black finish is said to add to the perceived value of the finished article.

Blackfast Chemicals, manufactures and supplies the Room Temperature Blacking Process for iron and steel. The process is said to be an inexpensive and convenient process developed for in-house use eliminating the need for metal parts to leave the production facility for finishing by an outside contractor. The process requires no expensive capital investment, short dwell time and replenishment is accomplished by ‘topping up’ when the solutions become weak so dumping of chemicals is not necessary. The uniform matt black finish is said to add to the perceived value of the finished article.

In response to demand for a process that will black stainless steel and most ferrous and non-ferrous metals, Blackfast Chemicals offers the LP process, a cathodic electrophoretic process for depositing a tough, black pigmented coating onto any substrate that can normally be electroplated – including aluminium, brass, stainless steel and zinc diecastings. It can also be used to produce other colours.

Blackfast Antiquing process is for darkening pewter, copper, brass, nickel and silver. Components can be relieved with an abrasive cloth if contrasting antique finish is required.

Blackfast Chemicals (Stand 5048)

T: 020 8336 2900