Nabtesco manufactures cycloidal gears that are ideal for use in medical technology. With its Vigo Drive eccentric gears and gear heads, the company is the world’s largest producer of precision gears, which are supplied to about 60 percent of all major robot manufacturers. Other areas of application for reduction gears include packaging systems, machine tools, welding systems, handling applications and antenna construction. With more than 5,000 employees in numerous production facilities and sales and service centres worldwide, Nabtesco offers comprehensive customer service for individual requirements.

Nabtesco manufactures cycloidal gears that are ideal for use in medical technology. With its Vigo Drive eccentric gears and gear heads, the company is the world’s largest producer of precision gears, which are supplied to about 60 percent of all major robot manufacturers. Other areas of application for reduction gears include packaging systems, machine tools, welding systems, handling applications and antenna construction. With more than 5,000 employees in numerous production facilities and sales and service centres worldwide, Nabtesco offers comprehensive customer service for individual requirements.

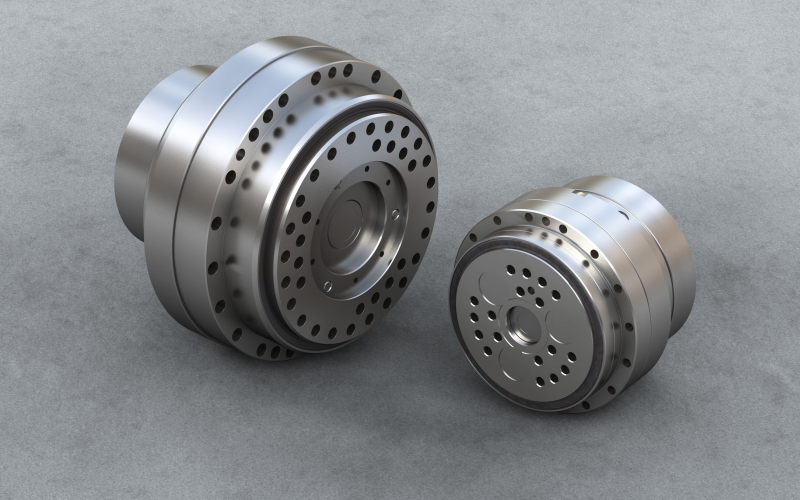

Precise, compact and reliable

The cycloidal gears of the RV-N and RH-N series feature above all precision, reliability and a compact design. The components are extremely reliable, quiet and precise so that they easily fulfil the requirements for drive technology used in medical imaging processes, such as X-ray, magnetic resonance imaging or ultrasound scanning, as well as patient positioning and shock-wave therapy.

Cycloidal gears: for safe technology around people

Cycloidal gears: for safe technology around people

Medical technology requires instruments or robots with extremely precise motorised drives for safe operation around people. In addition to precise positioning within a tolerance of millimetres Nabtesco Vigo Drive RV-N and RH-N cycloidal gears and gear heads are also designed with a high margin of safety to prevent injuries to patients and staff in the event of a disruption.

Nabtesco gears are also designed for a long life and stable operation, with an emergency stop torque of up to 5 times the rated torque; their overload capacity also allows them to move heavy loads. To minimise the noise level in the vicinity of the patient the reduction gears are available in a low-noise version.

Compact design with high performance: the Vigo Drive RV-N series

The compact cycloidal gears of the Vigo Drive RV-N series from Nabtesco feature a reinforced eccentric shaft bearing, which makes them extremely powerful. Their low weight provides for low mass inertia and improved load conditions. A special heat treatment process provides for high resistance to temperatures and a long life. The precision gears feature extreme rigidity and low backlash of less than one angular minute for precise and smooth positioning. They are available in diverse sizes with rated torques from 245 to 7,000 Nm.

RH-N cycloidal gears: with shaft and gearbox rotation

RH-N cycloidal gears: with shaft and gearbox rotation

Nabtesco gear heads of the RH-N series are designed for easy integration in X-ray, ultrasound and shock-wave machines, as well as MRI and CRT scanners. They are also suitable for automated patient positioning as well as transport on beds or tables. The innovative tribology concept guarantees extremely low-maintenance gears that are assembled in Germany and are available with a choice between shaft or housing rotation. The Vigo Drive RH-N series features gear heads with an integrated drive pinion and motor flange, therefore providing a plug & play solution for every machine design engineer.

Development from tier two to tier one supplier

Last year Nabtesco Precision Europe GmbH moved to a larger location in Düsseldorf, to enable custom adaptation, assembly and finishing of the cycloidal gears at the local level. This allows in-house production of custom and integrated eccentric gears to fulfil the diverse requirements for drive technology in medical applications and other industries. During the course of its history the company has also developed from a supplier of components (tier two) to a supplier of systems (tier one). The delivery of pre-assembled subsystems for easy integration in X-ray, ultrasound, shock-wave or MRI machines is therefore no problem for the gear specialist.

Nabtesco: a company’s success story

Nabtesco: a company’s success story

The Nabtesco Corporation was established in 2004 as a result of the merger of the mechanical engineering company Teijin Seiki Ltd. and NABCO Ltd. The idea for the merger of the two companies to create a global player in the field of precision gears originated in 2002 during cooperation in a project for hydraulic systems, in which both parties recognised the opportunities a merger would offer. The product lines and core technical competences complemented each other perfectly. The partners also found common ground in their strategic alignment and corporate philosophy. Consequently, the two enterprises merged in 2004 to form the Nabtesco Corporation. The Nabtesco Group is divided into the following divisions: “Precision Equipment”, “Transport Equipment”, “Industrial Equipment” and “Aircraft and Oil Hydraulic Equipment”.

Today, Nabtesco is the world’s largest manufacturer of precision cycloidal gears. With more than 30 years of experience in development and design, the gear manufacturer guarantees the highest level of quality in production and service.