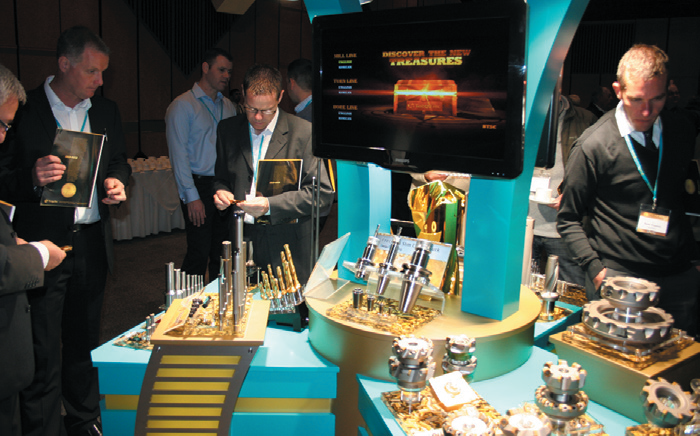

TaeguTec UK has launched its new Gold Rush series of cutting tools, presented at the Birmingham ICC to over 200 customers and distributors by IMC Group President and CEO Jacob Harpaz.

TaeguTec UK has launched its new Gold Rush series of cutting tools, presented at the Birmingham ICC to over 200 customers and distributors by IMC Group President and CEO Jacob Harpaz.

Harpaz says: “With industry demanding the capability to machine at high speeds with cutting tools that demonstrate a high level of edge toughness, our R&D teams have worked hard to deliver a range of products that offer high speed machining with excellent edge toughness. The result is the new Gold Rush range. We are now setting 45HRc as the minimum hardness level that all our cutting tools should be capable of machining at.”

The result with the new Gold Rush Series is a range of inserts that are finished to a polished standard and then given their unique ‘Gold’ coating for enhanced performance. The new coating that is available as a CVD or PVD option now delivers a smooth surface that improves chip flow whilst also improving the strength of the inserts. For turning applications the TaeguTec Gold Rush series now introduces the ceramic and SiN SC10 and AS10 grades for cast iron machining.

TaeguTec has also launched its new ‘Black Rush’ series of CVD coated inserts. The new TT7005 and TT7015 have been created to deliver exceptional performance levels on grey cast iron.

For general steel machining Harpaz introduced the new CVD coated TT8115, TT8125 and TT8135 that have been developed for general machining, continuous and interrupted machining respectively. This range is complimented by the TT9215, TT9225 and TT9235 CVD coated inserts for stainless steel and super alloy applications. More specific to stainless steel is the new TT5080 and TT9080 grades that are PVD coated.

With regards to milling, Harpaz introduced the new MillRush, Mill2Rush, Chase2Mill, Fineball and TopDrill Series, whilst more specific applications such as threading, boring and grooving have been extended with the launch of the new TopMini and TopMicro ranges.

TaeguTec UK T: 01937 589828