Warehousing and storage cover a wide range of activities that can result in various hazards. The harsh environment found in cold stores can exacerbate these safety implications and, as such, requires additional safeguards and training. Shaun Evers, managing director at Stonegate Instruments, looks at the potential risks and how technology can help employers protect their most valuable asset – people – from harm.

Warehousing and storage cover a wide range of activities that can result in various hazards. The harsh environment found in cold stores can exacerbate these safety implications and, as such, requires additional safeguards and training. Shaun Evers, managing director at Stonegate Instruments, looks at the potential risks and how technology can help employers protect their most valuable asset – people – from harm.

According to the Health and Safety at Work Regulations 1999, it is every employer’s duty to ensure that its workplace is safe and to assess and attend to any health and safety risks staff may be vulnerable to.

Employers are also obliged to provide the necessary protective clothing or equipment to ensure that safety signs are provided. In addition, if a company employs five or more staff it has to draw up a Health and Safety Policy statement, with emergency procedures.

Despite all these measures, sometimes even the best workplace health and safety arrangements can go wrong.

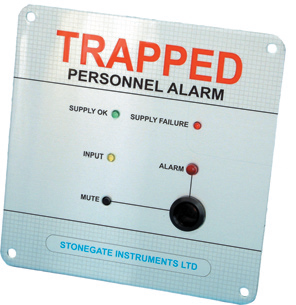

Many hazards, such as accidental lock-in, handling and accidental release of refrigerant, injury caused by a cold environment, ice build-up, increased risk of accidents, and increased risk of equipment failure are specific to cold stores, which can operate at temperatures as low as -30 °C. This means careful planning and a dedication to safety are top priorities for keeping workers injury free. One system that can help ensure the safety of cold store employees is a trapped personnel alarm, designed to monitor latching emergency push buttons located inside cold stores and give audio as well as visual alarms if someone is trapped. These can be panel, door or wall mounted, are backed up by batteries and have mains failure alert mechanisms, as well as mute and repeat features, and is activated when the person trapped in the cold store strikes the emergency alarm button. Another risk specific to working in cold stores is the handling and accidental release of refrigerant gases; equipment failure, improper maintenance work, mechanical damage or accidental release during refrigerant replenishment can all produce a potentially hazardous situation.

The greatest hazard comes from the release of ammonia, a toxic and flammable gas that should be handled with extreme care. Halocarbon refrigerants are of a lower toxicity but still pose a major risk.

The greatest hazard comes from the release of ammonia, a toxic and flammable gas that should be handled with extreme care. Halocarbon refrigerants are of a lower toxicity but still pose a major risk.

As such, it is essential to have a gas detection system – designed to detect gases, including ammonia and halocarbons – in place to prevent serious health problems or fatalities in the event of a refrigerant gas leak.

Companies using cold stores should also be aware of The Confined Space Regulations 1997 as dangers can arise in confined spaces because of lack of oxygen and, with cold stores specifically, through low temperatures.

Stonegate Instruments

T: 0113 224 4440