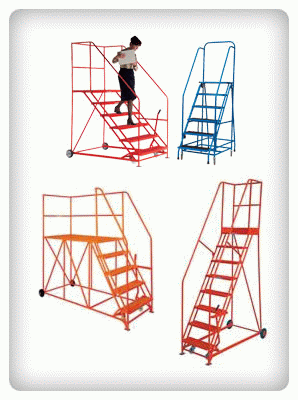

Mobile Safety Steps fulfil a very specialist and useful handling niche are becoming a common site in warehouses, stockrooms, DIY showrooms and factories. In our own warehouse we have many products that are too small to be moved with a forklift truck but still need to be placed at height – doing so with a ladder would be impractical. Mobile safety steps are completely self-supporting structures that have wheels or castors making them easy to move and allowing the operative to have both hands free when moving an item. With the medium to large safety steps that have a top level platform, there is the additional benefit of having a working area to move around on – this incidentally is also why they are being increasingly used in the building and aircraft maintenance industries.

Mobile Safety Steps fulfil a very specialist and useful handling niche are becoming a common site in warehouses, stockrooms, DIY showrooms and factories. In our own warehouse we have many products that are too small to be moved with a forklift truck but still need to be placed at height – doing so with a ladder would be impractical. Mobile safety steps are completely self-supporting structures that have wheels or castors making them easy to move and allowing the operative to have both hands free when moving an item. With the medium to large safety steps that have a top level platform, there is the additional benefit of having a working area to move around on – this incidentally is also why they are being increasingly used in the building and aircraft maintenance industries.

Variations

Smaller versions, with perhaps 2 – 6 steps, will likely have a handrail (although no platform) and have castors that retract when weight is applied to them thereby making them stable. If they are between 4 to 15 steps they will generally have a platform (on what would be the upper step), and will have surrounding handrails. This style of safety step are commonly made between 3 to 5 metres although there is at least one instance of the working height being 6 metres. Although at 6 metres they are still incredibly stable, above this height the weight becomes a limiting factor.

Smaller versions, with perhaps 2 – 6 steps, will likely have a handrail (although no platform) and have castors that retract when weight is applied to them thereby making them stable. If they are between 4 to 15 steps they will generally have a platform (on what would be the upper step), and will have surrounding handrails. This style of safety step are commonly made between 3 to 5 metres although there is at least one instance of the working height being 6 metres. Although at 6 metres they are still incredibly stable, above this height the weight becomes a limiting factor.

One last safety steps variation, is the single or double ended access platforms. As with other types of mobile safety steps, they can be secured by a hand operated lever, but will have a large platform allowing greater movement. With the double ended platform there will be two sets of steps with an extended platform in between.

Safety

Operatives should of course have appropriate safety wear and be aware of the dangers of working at height. Before using any mobile safety steps, the user should ensure that any castors will retracted or that the lever break (or foot operated lock) has been applied. The operative must test that the lever brake is working correctly before ascending the stairway. The units are designed to be used by one person at a time and in proper order should be very stable – clearly leaning over the edge would not be a clever thing to do! You are allowed to work with hand tools on safety steps, but if low voltage power tools are necessary, the work should be undertaken only under supervision and with the permission of the Officer of the Company responsible for plant and personnel safety. Safety gates can be fitted and there should be frequent inspections made for signs of damage.

Technical Specifications for Mobile Safety Steps

Mobile safety steps need to meet the ‘Industrial Duty’ Class 1 (BS2037) ladder standard – this is the strongest UK category with a maximum working load of 150kg or 23.5 stones. In reality, UK-made safety steps will considerably exceed these standards and have been tested at up to twice this working load. UK manufactured mobile safety steps are made of Trade or Industrial duty materials but cannot be kite marked because no kite mark applies to them.

When you think of all the advancements in recent years in handling equipment such as fork lifts, conveyors and stackers and so on, mobile safety steps seem very dated. However, they are extremely low maintenance and perform their required tasks extremely well.

Matt Janaway writes on workplace safety for The Workplace Depot.