Manager of Atlas Copco Compressors oil-free air division Paul O’Neill, outlines how to select the right air treatment equipment to prevent downtime and the resulting costs caused when water, oil, dust particles and micro-organisms affect compressed air.

Manager of Atlas Copco Compressors oil-free air division Paul O’Neill, outlines how to select the right air treatment equipment to prevent downtime and the resulting costs caused when water, oil, dust particles and micro-organisms affect compressed air.

The quality of compressed air has a direct bearing on production efficiency and end product quality, and when contaminated air comes into contact with production processes, the resulting equipment downtime and rejection costs can be unacceptably high. Indeed, the cheapest solution can quickly become the most expensive. To prevent this happening, it is essential that water, oil, dust particles and micro-organisms are eliminated from the delivered air.

The need to remove water

Air in the atmosphere contains moisture in the form of water vapour which the compression process releases a lot of. For example, a 100kW compressor drawing in air at 20°C and 60 per cent relative humidity will produce approximately 85 litres of water during an eight-hour shift.

That amount of water in compressed air has the potential to cause substantial problems resulting in high maintenance costs, shortened service life and impaired production performance. It can lead to increased leakage, disturbances in the control system and instrumentation, as well as shorter service life for the pipework system due to corrosion. However, the good news is that the water content can be separated out by using accessories such as aftercoolers, condensation separators and either refrigerant, absorption or membrane dryers.

Filter efficiency

Although modern fibre filters are very efficient at removing oil, it could be difficult to precisely control the quantity of oil remaining in the air after filtration. That is because temperature, among other factors, has a significant impact on the separation process.

Although modern fibre filters are very efficient at removing oil, it could be difficult to precisely control the quantity of oil remaining in the air after filtration. That is because temperature, among other factors, has a significant impact on the separation process.

Filter efficiency is also affected by the oil concentration in the compressed air, as well as the amount of free water present. The quantity of oil present depends, among other factors, upon the type and design of the compressor, as well as its age and mechanical condition. In modern, lubricated piston and screw compressors the quantity of oil is very limited. For example, in an oil-injected, screw compressor, the oil content in the air is less than 3mg/m3 at 20°C. But, although this volume of oil content may seem insignificant, and can be reduced further by using multi-stage filters, it is an idea to consider the potential quality limitations, increased risks and energy costs that it poses.

It is essential that oil vapour is removed using a filter with activated carbon. A correctly installed fibre filter, together with a suitable pre-filter, can reduce the quantity of oil in the compressed air to approximately 0.01mg/m3, but an activated carbon filter can reduce the concentration to 0.003mg/m3. This is because activated carbon is able to absorb 10-20 per cent of its own weight in oil.

Filters with activated carbon only remove air contamination in the form of vapour and should be preceded by other, appropriate filters. For optimal effect they should be placed as close as possible to the application site, be checked regularly and replaced frequently.

Removing micro-organisms

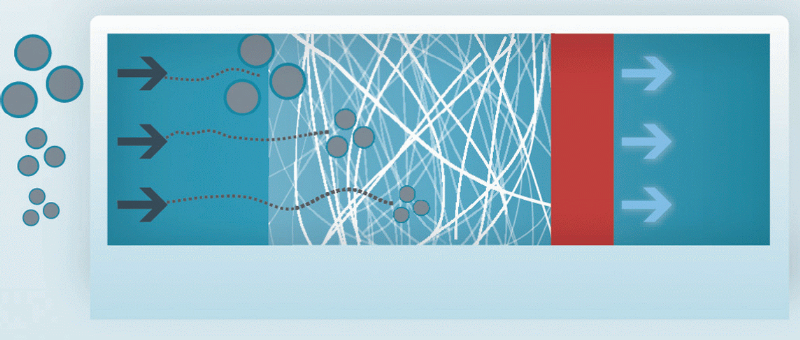

More than 80 per cent of the particles that contaminate compressed air are smaller than 2µm in size and can therefore easily pass through the compressor’s inlet filter, spreading throughout the pipework system and mixing with the water/oil residue and pipe deposits, resulting in the growth of micro-organisms.

Micro-organisms can germinate through the filter walls and therefore exist in the same concentrations on the inlet as well as the outlet sides of the filter. A filter positioned directly after the compressor can eliminate these risks but, to ensure pure compressed air quality, any bacterial growth after the filter must be kept fully under control. The most effective treatment involves drying air to a relative humidity of less than 40 per cent, achieved by using an appropriate dryer and including a sterile filter within the system.

It is essential that the filter is located in a housing that allows in-situ steam sterilisation or that can be easily accessed. Sterilisation has to be performed frequently to maintain good air quality.

Oil/water condensate

Oil in the form of droplets is separated partly in the aftercooler, condensation separator or a condensation trap and flows through the system with the condensation water. From an environmental point of view, this oil/water emulsion is classed as waste oil and therefore must not be drained off into the sewage system or directly into the environment.

Condensate disposal is subject to stringent laws with regard to the handling of environmentally hazardous waste. Disposal can be problematic but an easy and cost-effective solution involves installing an oil/water separator with a diaphragm filter to produce clean drainage water and to separate off the oil into a special receiver.

One safe solution

An oil-free compressor eliminates the need for an oil filter and guarantees freedom from contamination. An oil-free compressor can operate at a lower discharge pressure, thereby reducing energy consumption, and it has been shown in many cases that oil-free compressors offer the best solution from an economical standpoint and for the quality of air delivered.

Atlas Copco

T: 0800 181085