When new storage and order picking capacity has to be created with little complexity, Multi-Level Storage is the ideal solution. Shuttle XP systems link various company areas, accelerates processes, and can be built up to 30 meters high as standard.

When new storage and order picking capacity has to be created with little complexity, Multi-Level Storage is the ideal solution. Shuttle XP systems link various company areas, accelerates processes, and can be built up to 30 meters high as standard.

Current market drivers and market trends – such as rapidly growing e-commerce, ever more complex services, and faster delivery times – represent big challenges for companies. Production systems and storage logistics must be optimised to cut costs, improve productivity, and increase flexibility. When process complexity is constantly increasing, efficient storage and fast, complete, and reliable retrieval and distribution of goods are critical success factors that require optimal use of human resources, but also high-performance storage technology, which is achievable through modernisation. In view of the permanently growing range of goods and ever faster delivery times, quick access to the goods is also essential, for higher order picking performance with as few errors as possible.

High flexibility and density with large storage volume: High-performance, flexible, and efficient storage systems play a key role in mastering these challenges. Vertical Lift ‘Shuttles’ offers a range of significant advantages. It only needs a very small footprint, provides a very large amount of storage volume due to its height, permits highly dense storage of goods with flexible configuration options, and links several floors with one another. Furthermore, it can be integrated with existing storage systems. It also simplifies complex processes through automation and performs a buffering role for a smooth supply of goods at all times.

High flexibility and density with large storage volume: High-performance, flexible, and efficient storage systems play a key role in mastering these challenges. Vertical Lift ‘Shuttles’ offers a range of significant advantages. It only needs a very small footprint, provides a very large amount of storage volume due to its height, permits highly dense storage of goods with flexible configuration options, and links several floors with one another. Furthermore, it can be integrated with existing storage systems. It also simplifies complex processes through automation and performs a buffering role for a smooth supply of goods at all times.

Multifunctional and multiuser storage systems up to 38 meters high: Shuttle XP versions:

- The Shuttle XP 250/500 for loads of up to 560 kg which can be built at heights of up to 30 meters as standard, fits perfectly into the existing room dimensions, and provides maximum storage volume on a minimal footprint.

- The Shuttle XP 700 for goods weighing up to 725 kg is also available at heights of up to 30 meters as standard. It can be extended, downsized, reorganised, or adapted in any number of ways, depending on operating requirements, location, or what it is used for.

- The Shuttle XP 1000 for loads of up to 1,000 kg can be built up to 20 meters high. Depending on the unit type, load, and number of cycles, customised systems can be built at heights of up to 38 meters.

Extensive advantages for users: The user benefits of the storage system are extensive: Shuttles can if required, be up to 40 meters high as an individual solution, which can also link several floors. In addition, up to six access openings can be fitted in the standard configuration. All of these elements generate a more continuous and efficient material flow across a number of floors, with buffering options, consolidated work processes, optimised and accelerated cycles, and increased throughput.

Extensive advantages for users: The user benefits of the storage system are extensive: Shuttles can if required, be up to 40 meters high as an individual solution, which can also link several floors. In addition, up to six access openings can be fitted in the standard configuration. All of these elements generate a more continuous and efficient material flow across a number of floors, with buffering options, consolidated work processes, optimised and accelerated cycles, and increased throughput.

More continuous and efficient material flow and buffering functions: The compact design of Multi-Level Storage generally reduces the size of the footprint needed by between 40 and 85 percent. Highly dense storage and automatic height measurement increase the available capacity. The system significantly improves order picking performance, facilitates error-free picking, generates a direct flow of materials between the production area and warehouse, and optimises storage space, storage volume, and inventory management. The requested article is automatically conveyed to the order pickers at the storage unit’s access opening by means of the goods-to-person principle; throughput is increased by around 50 percent. Employees have to move around much less, which means that the travel time – the biggest part of the overall order picking time – is cut from about 65 percent to around ten percent.

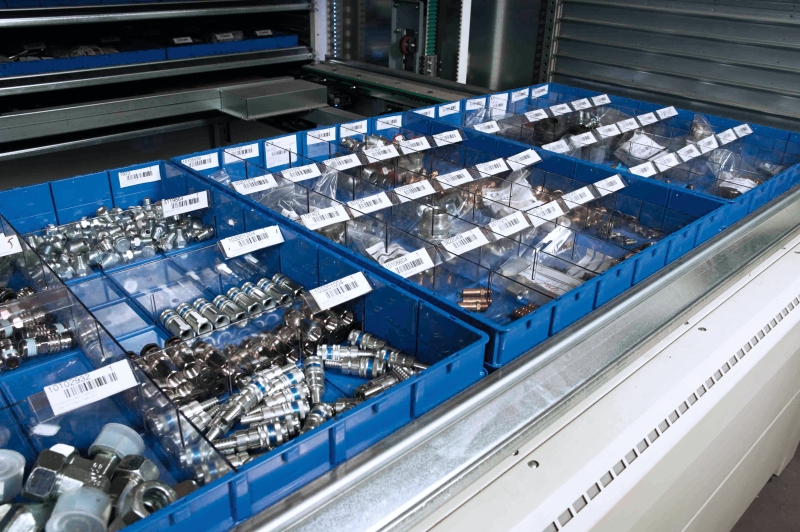

Fast order picking times and maximum accuracy: Fast and targeted access to stored goods prevents unproductive search times, significantly increasing throughput. The visual display elements at the access opening of the Shuttle XP help with error-free and fast order picking. The accuracy rate is more than 99 percent, an improvement of up to 50 percent. Further features of the Shuttle XP include the individually adjustable, ergonomic operator workstations, extensive safety devices for safe picking, and individually divisible trays for optimising the space available for storing goods of various sizes.

Fast order picking times and maximum accuracy: Fast and targeted access to stored goods prevents unproductive search times, significantly increasing throughput. The visual display elements at the access opening of the Shuttle XP help with error-free and fast order picking. The accuracy rate is more than 99 percent, an improvement of up to 50 percent. Further features of the Shuttle XP include the individually adjustable, ergonomic operator workstations, extensive safety devices for safe picking, and individually divisible trays for optimising the space available for storing goods of various sizes.

Suitable for use in a wide range of industries: Shuttles are suitable for use in a wide range of industries, including automotive, electrics/electronics, chemicals/ pharmaceuticals, machinery, maintenance, hospital logistics, the medical device market, and warehouse & distribution. For more information contact the home of the Shuttle, Kardex Remstar at info.remstar.uk@kardex.com or call us direct on 01992 557237